Manufacturer for Derrock Hyperpool PWP Screen - Replacement Screen for Derrock Hyperpool PWP – KANGERTONG

Manufacturer for Derrock Hyperpool PWP Screen - Replacement Screen for Derrock Hyperpool PWP – KANGERTONG Detail:

Description

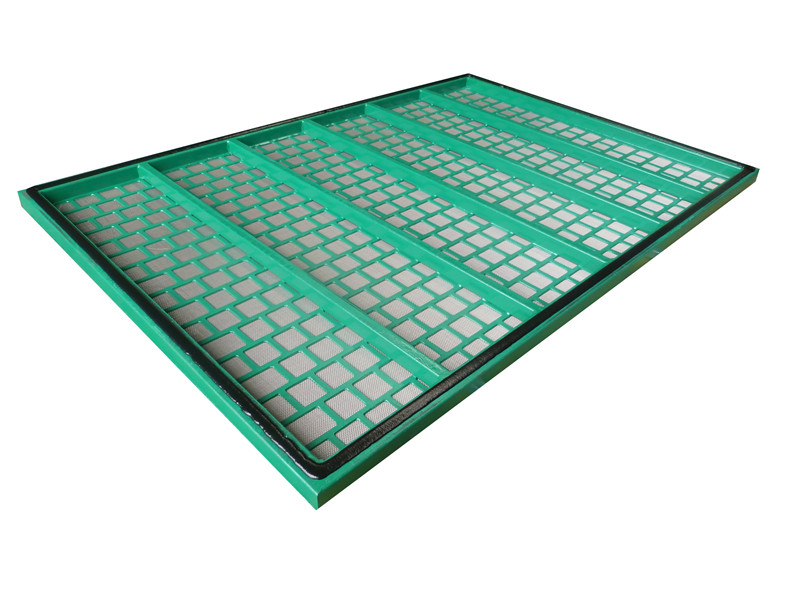

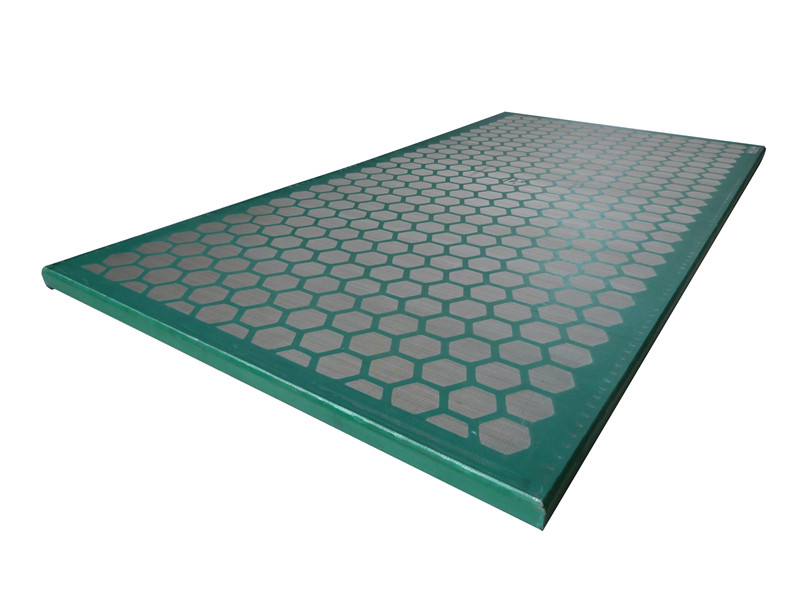

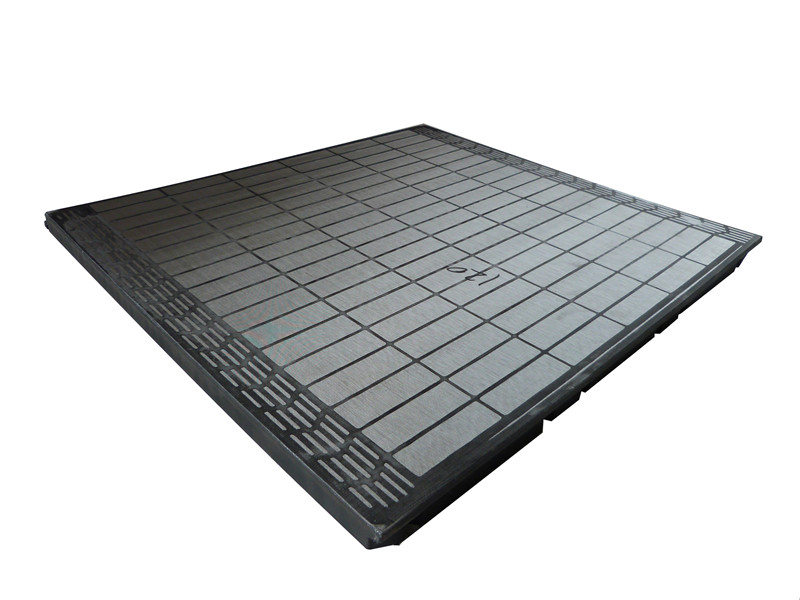

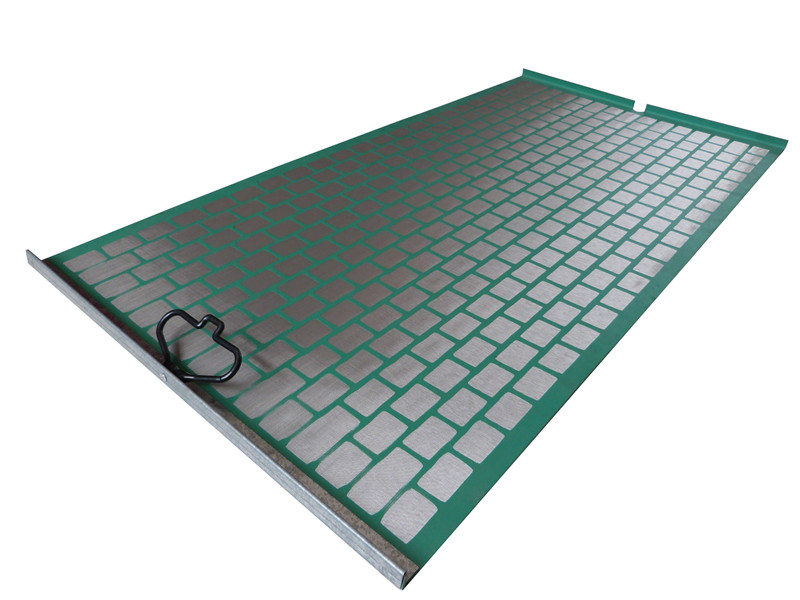

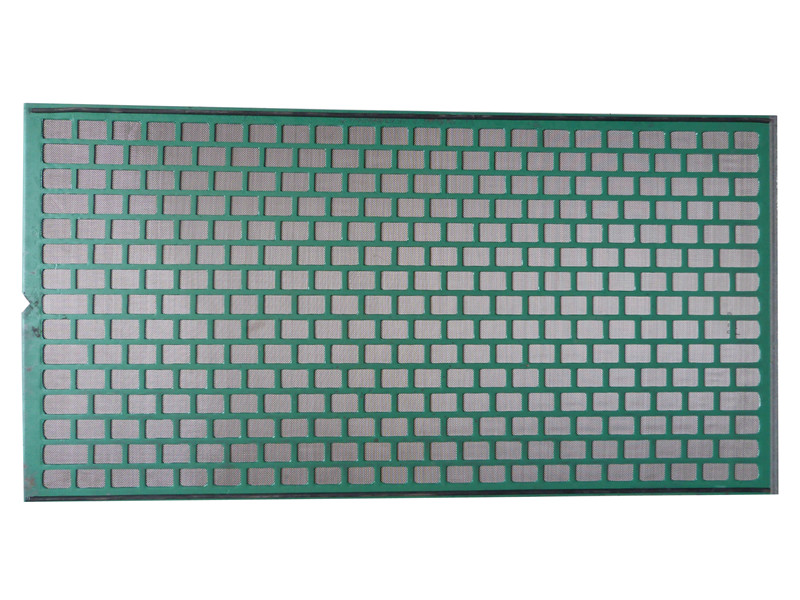

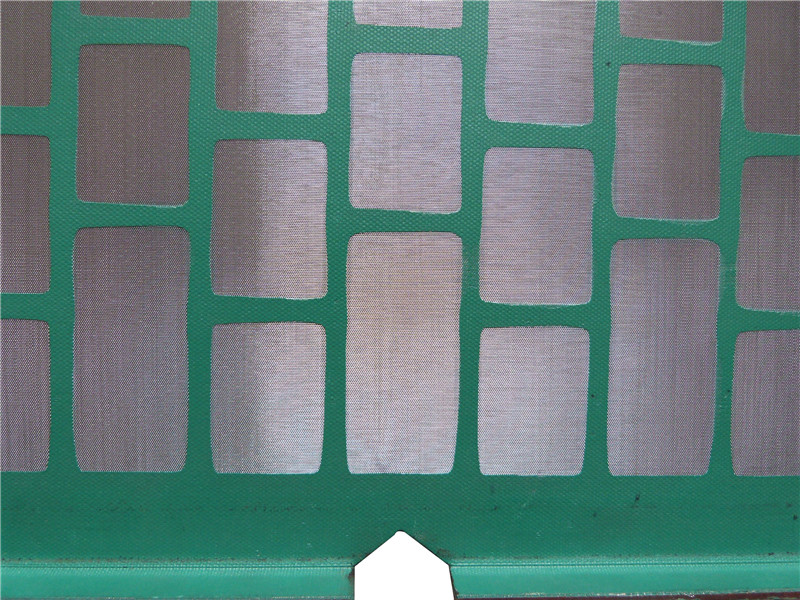

KET-PWP DH Shaker Screen is designed for the replacement screen of Derrock Hyperpool shale shakers. There is an operating handle on one side of the screen and a triangle breach in the center of the opposite side. Thanks to he machine assembled backside seal rubber, even the strip appears a small broken part, the other parts will be steady on back panel still. The most obvious advantage of Hyperpool PWP screen is better resistant to oil. And mesh sizes are commonly available from API 40 to API 270.

Adaptable Shale Shaker Model

KET-PWP DH shaker screens are used as the substitute screen for

Derrock Hyperpool 4-panel shaker.

Derrock Triple Hyperpool shaker.

Derrock Dual Hyperpool with mud cleaner.

Derrock Hyperpool VE (Vapor Extraction).

Competitive Advantage

Stainless steel 304/316 wire mesh for longevity.

Increase shaker capacity and reduce mud loss.

Scientific & reasonable cost control system for competitive price.

Higher flow rates without sacrificing cut point integrity.

API RP 13C (ISO 13501) compliant.

Adequate inventory in the shortest time to meet customers’ demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Weight (kg) |

|---|---|---|---|---|---|---|

| KET-PWP DH-A325 | DX | API 325 | 0.39 | 44 | 2/3 | 4.2 |

| KET-PWP DH-A270 | DX | API 270 | 0.67 | 57 | 2/3 | 4.2 |

| KET-PWP DH-A230 | DX | API 230 | 0.71 | 68 | 2/3 | 4.2 |

| KET-PWP DH-A200 | DX | API 200 | 1.32 | 73.3 | 2/3 | 4.2 |

| KET-PWP DH-A170 | DX | API 170 | 1.34 | 85.4 | 2/3 | 4.2 |

| KET-PWP DH-A140 | DX | API 140 | 1.89 | 104 | 2/3 | 4.2 |

| KET-PWP DH-A120 | DX | API 120 | 1.89 | 117.8 | 2/3 | 4.2 |

| KET-PWP DH-A100 | DX | API 100 | 2.66 | 142 | 2/3 | 4.2 |

| KET-PWP DH-A80 | DX | API 80 | 2.76 | 170.4 | 2/3 | 4.2 |

| KET-PWP DH-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 4.2 |

| KET-PWP DH-A60 | DX | API 60 | 4.1 | 268 | 2/3 | 4.2 |

| KET-PWP DH-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 4.2 |

| KET-PWP DH-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 4.2 |

| KET-PWP DH-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 4.2 |

| KET-PWP DH-A20 | DX | API 20 | 10.88 | 809 | 2/3 | 4.2 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||

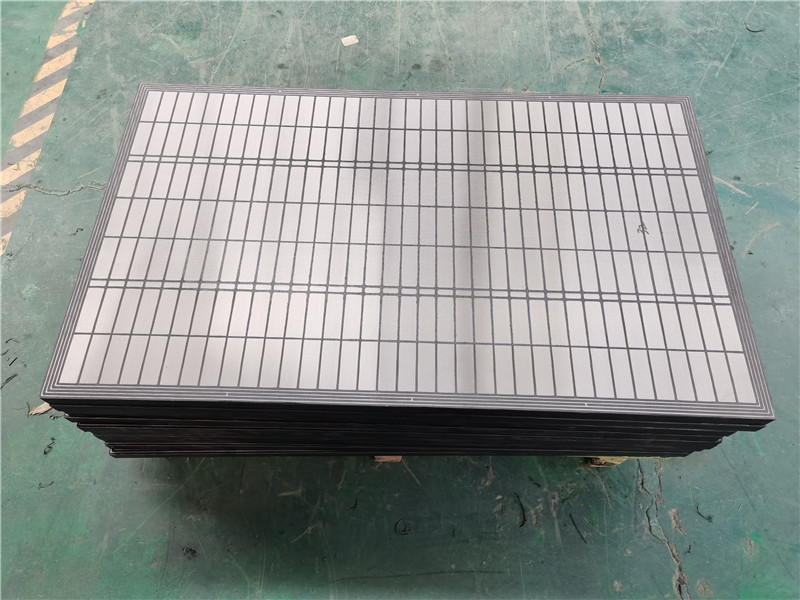

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Manufacturer for Derrock Hyperpool PWP Screen - Replacement Screen for Derrock Hyperpool PWP – KANGERTONG, The product will supply to all over the world, such as: Denver, Nicaragua, Singapore, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've got better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you require.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.